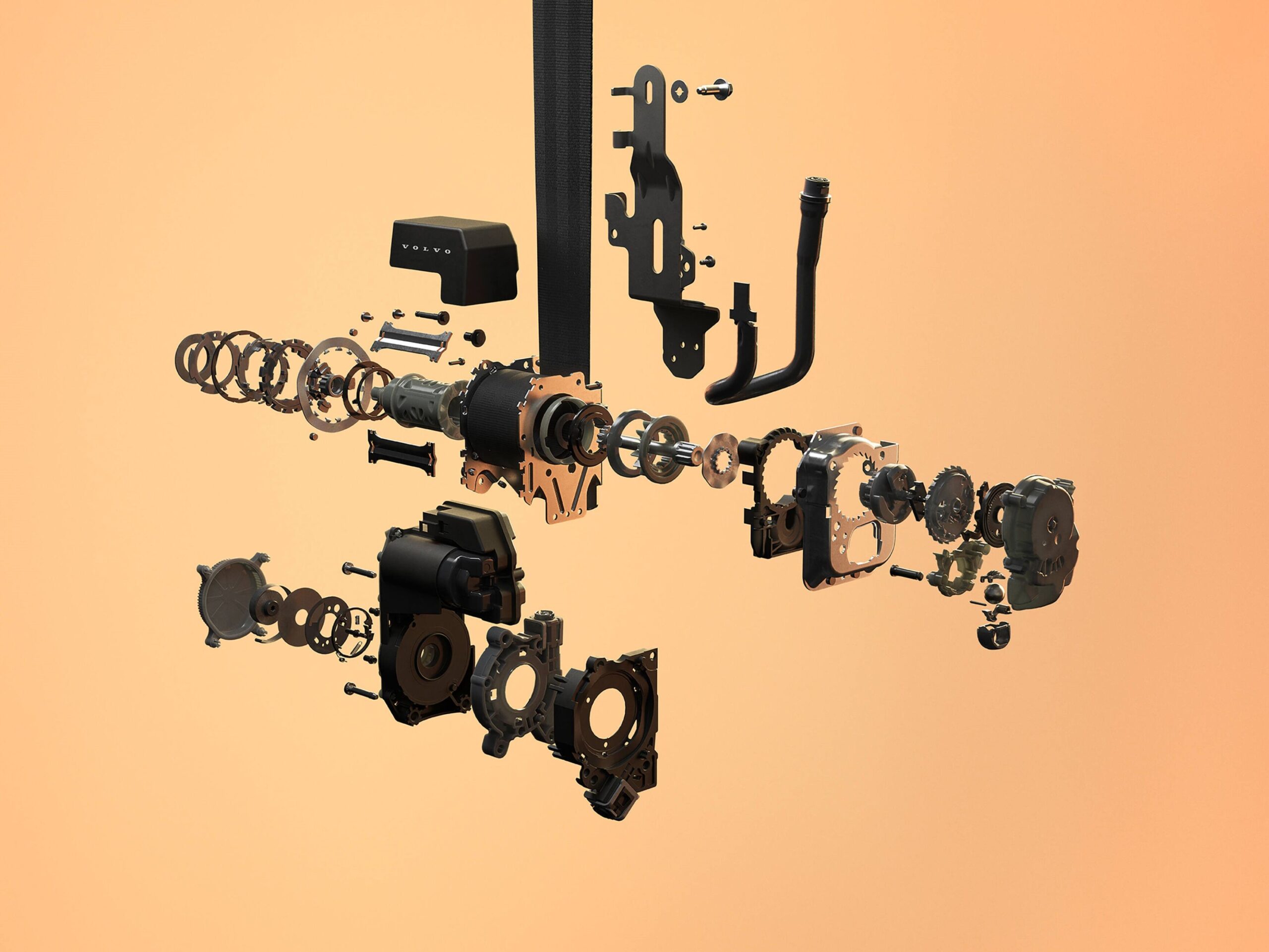

Today, Volvo Cars unveils a major safety improvement to the safety belt. The new multi-adaptive safety belt is a world-first technology aimed to further enhance safety for everyone in real-world traffic situations.

Debuting in the upcoming fully electric Volvo EX60 in 2026, the new safety belt is designed to better protect people by adapting to traffic variations and the person wearing it, thanks to real-time data from the car’s advanced sensors.

The new multi-adaptive safety belt can use data input from interior and exterior sensors to customise protection, adapting the setting based on the situation and individual’s profiles, such as their height, weight, body shape and seating position. For example, a larger occupant in a serious crash will receive a higher belt load setting to help reduce the risk of head injury. While a smaller occupant in a milder crash will receive a lower belt load setting to reduce the risk of rib fractures.

This is achieved by significantly increasing the number of so-called load-limiting profile variations, which manage the force applied to the occupants in the event of an accident. And thanks to over-the-air software updates, it gets better over time.

“The world first multi-adaptive safety belt is another milestone for automotive safety and a great example of how we leverage real-time data with the ambition to help save millions of more lives,” says Åsa Haglund, head of Volvo Cars Safety Centre. “This marks a major upgrade to the modern three-point safety belt, a Volvo invention introduced in 1959, estimated to have saved over a million lives.”

Leveraging data to improve safety

Thanks to over five decades of safety research and a database of over 80,000 occupants involved in real-life accidents, Volvo Cars has built unique safety knowledge capturing the complexity of the real world. It sets the foundation for the company’s safety innovations over the years and the pioneering Volvo Cars Safety Standard, which exceeds official testing requirements.

Building on Volvo Cars’ long history of creating cars with the ambition to be equally safe for everyone based on real-world data, the company has been exploring new technologies to better protect different people in various crash scenarios.

Modern safety belts use load limiters to control how much force the safety belt applies on the human body during a crash. This new safety belt expands the load-limiting profiles from three to eleven and increases the possible number of settings, enabling it to optimise performance for each situation and individual.

Unlike traditional systems, the new multi-adaptive safety belt can utilise data from different sensors, including exterior, interior and crash sensors. In less than a blink of an eye, the car’s system analyses the unique characteristics of a crash – such as direction, speed, and passenger posture – and shares that information with the safety belt. Based on this data, the system selects the most appropriate setting.

Better over time

The capabilities of the new multi-adaptive safety belt are designed to continuously improve via over-the-air software updates. As Volvo Cars gathers more data and insights, the car can improve its understanding of the occupants, new scenarios and response strategies.

The new safety belt is part of Volvo Cars’ broader safety ecosystem, working seamlessly with airbags, occupant detection and driver assistance systems. This cooperation provides harmonised protection features, enhances effectiveness and minimises the risk of subsequent injuries.

The belt has been tested and further developed at the Volvo Cars Safety Centre crash lab, which celebrates its 25th anniversary this year. In the industry-leading crash lab, Volvo Cars’ safety engineers can recreate almost any traffic accident and perform tests that exceed regulatory requirements for real-world safety. This multifunctional facility has been essential for Volvo Cars to maintain its position as a leader in automotive safety.